|

|

|

|

|

Hot Air Soldering Hot Air Pencil SMD Rework PCB Repair Non-Contact Touch-Free Micro Soldering for Ceramic Caps

|

|

|

|

|

|

|

|

|

|

| History & Theory of

Operation: |

|

|

|

|

|

|

|

|

|

|

™

A Hot Air Pencil Should Be "Pencil" Thin To Provide Chip Visibility ™

A Hot Air Pencil Should Be "Pencil" Thin To Provide Chip Visibility

|

|

| |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

Copyright © 1996, 2008, 2009, 2010, 2011 and 2012 by David Jacks

|

|

|

|

| |

|

|

|

|

|

|

Zephyrtronics Equipment is Designed, Engineered,

and Manufactured in the United States of America.

ZeroTouch™

Soldering

|

|

|

OVERVIEW: |

|

|

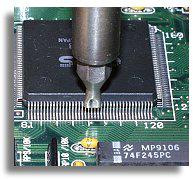

A Hot

AirPencil is Shown Above Used

In Concert With a

Bottom-Side Preheating AirBath.

Micro Soldering for

Microscope Soldering |

|

The

introduction of the hot air pencil as a soldering device

for surface mount devices for high quality soldering

reflow on PCB's

at a bench

--- whether in prototype, design or rework/repair

--- along with bottom-side PCB preheating seems

obvious now, but it it was not always so.

The hot air pencil made its entry into the PCB

production world in the 1990's almost 10 years

after the advent of surface

mounted technology.

Together, the AirPencil™

with preheating proved that it was then possible to

mimic the initial production soldering thermal profiles,

processes and equipment.

|

|

|

|

Even the briefest study of

any state-of-the-art, high volume PCB production process

--- along with the most basic semiconductor data books

--- will emphasize how precise handling

methodologies and exacting solder reflow prerequisites

are essential for many very critical quality reasons.

And since it only logically follows that all PCB tasks

performed at a benchtop should be held to the same equal standard

of high-volume production, some fundamental conclusions can be made

as just how to achieve premium solder joints at the bench: |

|

|

|

|

|

|

|

|

|

|

|

|

-

All PCB's should be

carefully thermally

ramped 2ºC-4ºC per second

with a preheating “soak” prior

to soldering or desoldering tasks whether in

production, prototyping or in rework or repair.

-

Non-contact and

non-contaminating hot air soldering (convection)

is best suited for ceramic chip resistors and

capacitors.

-

Non-contact and

non-contaminating hot air soldering (convection)

is best suited for placement of fine pitch and

ultra-fine pitch semi-conductors.

-

When hot air is used

to remove or replace SMD's, the air-stream must

be pin-pointed precisely to the targeted leads

and pads with a

hot air pencil

or with extra-low velocity

hot air nozzles

if with a larger SMD/BGA Hot

Air Benchtop system.

|

|

|

|

| |

-

Components adjacent

to an SMD that is being removed or replaced

should never be exposed to elevated reflow

temperatures.

-

PC boards and their

components should never be subjected to

temperatures greater than originally seen during

initial production reflow.

-

An accelerated cool

down of the solder joint is desirable and

recommended to insure robust joints and to

prevent accidental skewing, misalignment, and/or

tomb-stoning.

-

Static-sensitive

electronic components should be protected during

printed circuit board assembly rework from

accidental static discharges. And the use of an

ESD wrist strap by the rework engineer or

technician is recommended.

|

|

|

|

|

|

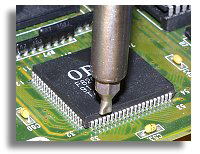

The Hot AirPencil

is Shown Above Soldering a Quad Flat Pack (QFP). Notice the 100%

Non-Contact of the AirPencilto Delicate Leads. |

|

A BRIEF HISTORY: CONVECTIVE vs CONDUCTIVE REFLOW:

PCB soldering generally is divided into

two methods: convection and conduction. With the advent of

SMD's and chip miniaturization, any physical contact, conductive soldering

quickly lost favor with manufacturing and quality engineers. High volume conveyor ovens and hot air equipment (convective)

quickly became preferred over the traditional contact methods (conductive) such as

soldering

irons, hot bars, thermodes and even wave soldering. |

|

|

Creating

electrically sound and physically robust solder joints --

between a chip's leads and its tinned copper pads -- requires

attention to many process parameters. Within even the most

nominal PCB assembly, a host of dissimilar materials can be

found: copper, fiberboard, ceramic, plastic, tin, lead,

silicone, laminates, and more. Each of these distinct materials

have varying thermal expansion rates. If ignored during exposure

to solder reflow temperatures, many compounding problems. |

|

|

|

|

|

|

|

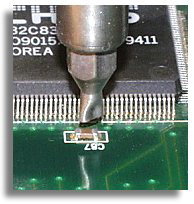

Ceramic Chip Resistors & Caps

& the Hot Air Pencil. As the transition from Thru-Hole to SMT accelerated, an immediate drawback with the use of soldering irons and hot tweezers

appeared: miniature ceramic chip capacitors and resistors

cracked or fissured when soldered to the PCB. The cracking problem

rose up from the severely unequal expansion rate

between the ceramic chip and its leads created by contact soldering

irons. Thus, pin-pointed hot air soldering became the

favored method. But how best to do it?

In 1994, Randy Walston

and I introduced the first true

hot air pencil

to the soldering market to great fanfare at the

NEPCON West Electronic Exposition in Anaheim,

California. In fairness, there had been other

hand-held hot air soldering tools on the market, but

they were either large in diameter, bulky, awkward

to hold, blocked the vision of a technician from the

chips to be soldered, powered by high voltages where

transient leaks and switching voltage spikes put

noise into the power lines (and damage SMD's if

touched), or were re-packaged hot air "tools" inside

of existing soldering iron handles. The

patented AirPencil™ design stole the show attended

by nearly 40,000 engineers, technicians, designers,

manufacturers and quality personnel. Over 2,000

written inquiries to the show's administrators were

submitted. |

|

|

|

Today, most every

manufacturer of ceramic capacitors and glass diodes have

published papers and warnings that they are not responsible for

damage done to their ceramic caps induced by hand soldering

irons because of the above stated problems and state that

soldering irons are prohibited as soldering tools with their

devices.

Yes, one could remove a

chip quickly with a heated contact tool (soldering

iron or hot tweezers), but once removed, the chip

could not be re-used.

Cracking & Fissuring:

More importantly, soldering new ceramic chip

capacitors and resistors with contact type tools

became prohibited by many prestigious electronic

firms to prevent chip cracking/fissuring.

Instead of the soldering iron and hot tweezers, the

hot air pencil quickly became the preferred tool for

soldering ceramic chip SMD's. Moreover, the hot air

pencil proved most effective in the removal of chip

capacitors, chip resistors, and SOIC's when utilized

with

(non-heated) tweezers.

Also, hot air pencils,

not soldering irons, became preferential preparing

or "touching up" pads. Soldering irons can leave

tags or ice cycles on the pad causing co-planarity

problems at the lead/pad interface. A hot air pencil

leaves a smooth pad. This process is now known as

hot air leveling. |

|

|

|

More Advantages of

Non-Contact Soldering:

The beneficial

applications of the hot air pencil quickly transcended more

than just ceramic chip caps, resistors, and SOIC's. The hot air

pencil quickly proved to be superior for soldering of a newer type

of SMD: fine and ultra-fine pitch devices (FPT & UFPT).

Between 1988 and 1995,

demand by designers for higher I/0 counts on IC's

pushed electronic packages to extremes. Earlier

SMD's had lead counts at 100 or less with pitch

spacings typically between 0.040" and 0.050", but

newer FPT and UFPT chips had I/O counts as high as

250 plus. Complicating things further, these devices

had pitches as small as 0.015".

In 2004, NASA

heralded the "touch-free, precision soldering

method" of the patented Zephyrtronics AirPencil™

in

a 104-page report recognizing the aforementioned

attributes of pin-pointed hot air for PCB tasks.

"Touch-free." Perfectly said.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Limitations of Hot Contact Tools and

QFP's. Where hot

contact soldering irons, hot bars, and hot tweezers were

inadequate for the placement of ceramic chip capacitors

and resistors, the limit of their usefulness became more

apparent with the arrival of these ultra fine pitch

components like Quad Flat Packs (QFP's). Chip

miniaturization also translated into tinier leads, too. |

|

|

|

In fact, the component's leads

spotlighted the disadvantage of soldering irons when compared to the non-contact (hot air) method. The leads became so

delicate, so small in overall footprint (width, thickness, and even extension of the toe) that they proportionately became extremely susceptible to bending, twisting out of their axis and deforming whenever touched by a contact type tool. |

|

|

|

The Hot AirPencil

is Shown Above Soldering a PLCC Package. Notice the 100%

Non-Contact of the AirPencil to the Delicate Leads. |

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

Advantages of Hot Air Pencil Over Hot Contact Tools.

An AirPencil™ hot air never "touches" the component or its

tiny, fragile, and weak leads. The opposite is true of the hot

contact reflow tools where the tool can "stick" to SMD leads,

bend SMD leads upwards/downwards causing co-planarity problems, tweak SMD outwards/ inwards causing electrical shorts or

opens. The AirPencil™ pencil presents none of these

problems. It allows no opportunity for introducing contamination

to the PCB as opposed to the hot contact tools. Dirt, grime, residual flux and adhesives can and often

stick to contact tools cross-contaminating PCB...and creating even more quality problems. |

|

|

|

|

Plus, the

AirPencil™ can be used to gently pre-heat the surrounding area of

a targeted chip before soldering or desoldering so lower temperature settings and shorter reflow dwell times

can be achieved.

Of course, the preferred and most quality-effective, auxiliary compliment to the

hot AirPencil™ is a temperature-controlled,

bottom-side, forced-convection preheating system.

Such a mild pre-heating of the PCB right at the bench can really be of great assistance when processing PCBA's with heavy ground planes, multi-layers, or large heat sinks.

-- David Jacks, 1996

Los Angeles, California |

|

|

Ceramic Capacitors

Must Be Reflowed With a Hot AirPencil Instead of a Contact-Style

Soldering Iron Which Fracture and Crack the Chips. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

********************* |

|

|

|

ABOUT THE AUTHOR:

David Jacks was Director of Engineering with

the two largest soldering equipment manufacturers in

the world, Weller®

and Ungar®

collectively for over 14 years before founding the

Zephyrtronics®

company in 1994 with his fellow design engineer Randy Walston.

In the 1980's, David played a significant role in

helping the printed circuit industry transition to

surface mount from through hole technology. |

|

|

|

David's

professional product design career as an inventor stretches from the early

1970's in Los Angeles. His original groundbreaking designs and products have been

spotlighted in feature articles in both Popular Science®

and Popular Mechanics®

Magazines, a rare accomplishment.

For decades, David designed award-winning products,

appliances and tools for many global iconic brands.

|

|

|

|

David's original products have been marketed by Sears®,

Black & Decker®,

RadioShack®,

Motorola®,

Snap-On Tools®,

Rubbermaid®,

CooperTools®,

Farmer Brothers®

and Brewmatic®,

Weller®,

Ungar®

among others. David holds multiple patents (utility and design) for his many

inventions; has authored technical articles for national journals and routinely speaks to electronic professional societies. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

| |

|

©1996 - 2011, 2012,

2013, 2014, 2015, 2016, 2017-2018, 2019,

2020 - 2024 by Zephyrtronics®. All rights reserved.

The information, text, images, photographs, charts, graphs you

receive online from Zephyrtronics® are protected by the

copyright laws of the United States. The copyright laws prohibit

any copying, redistributing, retransmitting, or repurposing of

any copyright-protected material. Zephyrtronics is the

registered trademark property of JTI, Inc. "The Science of

Zephyrtronics" and "Simplicity Through Innovation" and "Zephlux"

and "ZeroLead" and "Zero Balling" and

"ZeroTouch" and "Zero Residue" and "Post

Cooling" and "Post Cooler" and "AirBath" and "SolderGlide" and

"ZeroTouch" and "SolderMill" and "Just So Superior" are the protected trademark

property of JTI, Inc. "Zephyrtronics" and "Low Melt" and "Air

Fountain" and "Fountainhead" are the registered trademark

properties of JTI Inc. *The above names are the registered

property of their respective owners. |

|

|

|

|

|

|

|

| |

|

| |

|

SMD

Rework,

SMT Rework

AirBath Air Bath,

SMD Rework Stations,

Hot Air Pencil Soldering,

BGA Rework Stations,

CSP Rework Stations,

Preheating Systems,

PCB Preheaters,

Pre-Heat SMT/ SMD,

Low Temp Rework,

SMT DeSoldering Tools,

Vacuum Pickup Tools,

Circuit Board Holders,

PCB Fixture & PCB Holders

&,

Board Cradles,

Rework Solder Paste,

No-Clean Solder Paste,

Low Melt®

De-Solder Wire,

DeSolder Wire,

Hot Air Rework Stations,

Fume Extractors,

SMT Dental Probes,

SMT, SMD Rework Kit,

BGA Rework Kit,

LMK Kit,

BGA Re-Balling Kit,

SMD Tweezers,

Power Palm Plunger,

QFP Lead Straightener

How

To - SMT, CSP, BGA Rework

How To - BGA Alignment;

How To - SMT Rework;

How To - PCB Preheating,

How To - BGA & CSP Rework;

How To - Quickly Solder

SMD Packages Effectively;

How To - CSP Alignment;

How To - Lead-Free Rework;

How To - SMD Removal

Economical;

How To - SMD Removal

Professional;

How To - Hot Air Pencil /

AirPencil Soldering;

How To - SMD Quick Chip

Removal;

How To - BGA Re-Balling;

How To - Rework PLCC, QFP,

QFN, LCC, SOIC, SOL, Shielded SMD, TSOP;

How To - Solder & Rework

Ceramic Capacitors;

How To - Solder & Rework

Glass Diodes;

How to Repair Smartphones,

Tablets and Laptops

Soldering,

De-Soldering

Soldering Accessories,

Solder Wire,

No-Clean Solder Wire,

Eutectic Solder Wire,

Solder Wire Dispenser,

Solder Paste,

Lead-Free Solder Paste,

Flux,

Solder Paste Dispensers,

Low Melt®

DeSolder Wire,

De-Solder Wire,

Soldering Tips,

Thru-Hole DeSoldering

Tools,

DeSoldering Tips,

Tips for DeSoldering,

De-Solder Wick &

DeSoldering Braid,

Smoke Extractors,

Fume Extractor Filters,

Carbon Activated Filters,

SolderMill™,

Solder Sucker / DeSolder

Pump,

Pre-heating Systems,

Preheat Thru-Hole,

PCB Pre-heaters,

Flux Solvent,

How To - Connector Rework;

How To - PC/104 Soldering

and Rework;

How To - Thru-Hole /

Through Hole Desolder / De-Solder;

How To - Low Melt®

Desolder Wire;

How To- Stop Lifting Pads;

How To- Desolder /

De-Solder Heavy Ground Planes;

How To - Lead-Free

Soldering and De-Soldering;

Pre-Heaters for Lead-Free Rework and Soldering

Dispensing Equipment, Gear, Supplies, Dispensing

Bottles & Dispensing Accessories

Dispensing Systems,

Dispensing Syringes,

Dispensing Barrels,

Tapered Dispensing Tips,

Blunt Needles,

Dispensing Bottles,

Stainless Steel Needles,

Dispensing Needles,

Industrial Needles,

Dispensing Tips,

Industrial Dispensing

Tapered Tips and Needles,

Dispensing Accessories,

Flux Bottles,

Solder Paste in Syringe,

Paste Rack Solder Paste

Holder™,

Dispensing Supplies,

Power Palm Plunger,

Manual Dispensing,

Alcohol Pump Bottles,

Automatic Dispensing,

Squeeze Bottles, Wash

Bottles, Brush Bottles, Spout Bottles, Pump

Bottles

Benchtop Accessories,

Bench Supplies,

Benchtop Tools

SMD Solder Paste,

Solder Wire,

LowMelt®,

No-Clean Flux,

BGA Flux,

Rework Tack Flux,

Non-Flammable Flux Remover,

Pen Vac,

SMT Tweezers,

Fume Extraction,

SMD Tweezers,

PC Board Fixtures,

Hot Air Tips,

AirTips,

Replacement Soldering

Sponges,

Iron Plated Soldering Tips,

Foam Swabs,

Anti-Static Foam Swabs,

Thru-Hole & Solvent

Brushes,

Helping Hands,

LMK Rework Kits,

X-BOX 360 Repair,

Wire Strippers & Wire

Cutters,

Flush Cutters, Micro

Shears & Needle Nose Piers,

Straightening Tool for

QFP Leads,

ESD Wrist Straps,

ESD Wrist Strap Tester

Updated

for September 21 , 2024 |

|

|

|