|

|

|

How to Align a BGA Placing the Ball Grid Array to the PCB How to Prepare BGA Pads Soldering BGA's

|

|

HOW TO ALIGN & PLACE BGA'S and

HOW TO REDRESS BGA PADS

|

|

NASA & Zephyrtronics Show How To:

ALIGN QUICKLY & EASILY BGA’s & CSP’s PRECISELY TO PADS IN SECONDS!

|

|

|

|

|

|

|

|

|

|

|

Early 1990’s:

Zephyrtronics

engineers

had the foresight to resolve the issue of placing BGA’s to

the PCB pads. Their patented invention, method and

its trademarked, famous cubic design, long used successfully and repeatedly by

thousands of engineers and technicians makes aligning BGA's

to the BGA pads:

1) Easy to Perform. (Little Skill

Required)

2) Quick to Perform. (Less than one minute!)

3) Accurate & Repeatable Placement

4) Inexpensive and

Kind to Your Budget! |

|

|

|

Our patented Zephyrtronics BGA Alignment Template Invention

eliminates the need for expensive so-called

“split-beam” vision machines, cameras and monitors,

all of which (by the way) must be continuously

calibrated.

Below are photographs from

Zephyrtronics and from NASA showcasing the easy,

reliable five step process for aligning and

reflowing the BGA right to the corresponding PCB

pads with the world-famous, immediately recognizable

trademark design. |

|

|

|

|

|

|

|

|

| |

TM

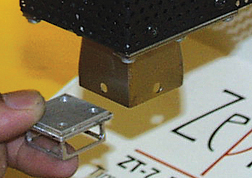

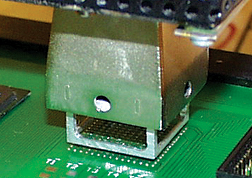

STEP 1:

First, insert the patented &

trademark Alignment Cube into corresponding,

non-heated nozzle. Next, activate the ZT-7’s

vacuum to secure Cube within nozzle as shown.

|

|

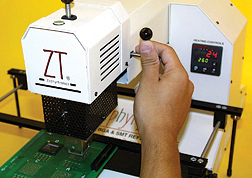

STEP 2:

Lower “Z” Axis of ZT-7 To Where Alignment

Cube Hovers Directly Over (NASA Recommends About 1mm

Above) the Targeted BGA Pads on the PCB Below.

|

|

TM

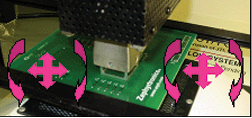

STEP 3:

Moving the Adjustable Board Cradle (PCB

fixture), next

“Align the PCB’s

pads for the targeted BGA to the Alignment

Tool by adjusting the ABC-1 Circuit Board

Cradle as necessary.”

-- NASA '04.

Photo Courtesy

of NASA

|

|

|

|

|

|

|

|

|

|

|

|

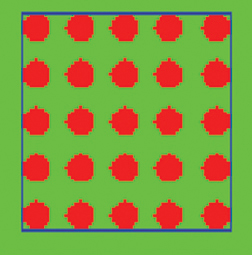

STEP 4B:

NASA explains

the alignment simplicity this way: “The

alignment process is completed when the

solder pads are just hidden on all

directions. The drawing (above) shows what a

properly aligned 5 x 5 BGA would look like.

The solder pads (red) are just contained the

Alignment Tool outline (blue).”-- NASA, '04.

Illustration courtesy of NASA from NASA

Report describing the Zephyrtronics patented

BGA alignment template and methodology. |

|

|

|

| |

TM

STEP 4A:

Square & Mate the Cube to Outside Perimeter

of BGA Pads. The Nozzle’s X, Y and Theta are

Now Precisely Relationed to Targeted Pads!

Cube Temporarily “Holds Place” for the BGA.

Raise “Z” Axis, Deactivate Vacuum Releasing

Cube. The next helpful illustration expands

on the alignment concept a bit more. |

|

|

STEP 5:

Insert

Your BGA/CSP into the Now-Aligned Nozzle

Where the Cube Had Been. Activate Vacuum to

secure BGA. Lower “Z” Axis and Nozzle Down

to the Substrate. Release Vacuum. Your BGA

is Positioned on to Corresponding Pads! You

are now ready to reflow your BGA with your

Zephyrtronics

ZT-7

System. How easy is that?

|

|

|

|

|

|

|

|

|

The Very Sad History of "BGA Machines"

|

|

| |

Unfortunately (seriously unfortunately), there have

been a lot of truly awful and very expensive

"machines" released to the market since the 1990's

to "address" BGA work at the bench. Many of these

albatrosses were marketed by some of the most

well-known brands in the soldering benchtop

industry...and worse, well-intentioned engineers and

technicians were "sold" these machines at prices

ranging from $20,000 to $60,000.

Most

of these machines had so-called "split beam"

alignment prisms on the market hitched to a camera to superimpose

the image of the BGA over the image of the pads on

the PCB. This camera/prism arrangement was from the

beginning plagued with inaccuracies and "offsets"

from a mere bumping of the bench they rested on.

Now, we see these companies -- ten years later --

without any shame whatsoever introducing yet more

"new" machines without the split-beam (which was

never needed in the first place) and obsoleting

their former models leaving their customers without

any service or spare parts and stuck with machines

that won't work. We know. We speak to them all the

time.

Worse, these same companies now have the gall to

criticize "split beam vision" systems as

they advertise

their latest new machines. Really! Buyer beware. |

|

|

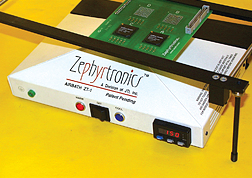

The Zephyrtronics ZT-7: Fifteen Proven Years

|

|

|

The

ZT-7 has

been on the market since 1998 and is still the

number one system on earth with a customer base as

sterling as it gets. The

ZT-7 is at

work as you read this webpage around the planet in

every field where PC board assembly work, rework,

repair or prototype design is done.

Zephyrtronics was ahead

of its time with the first single-spot, single-axis

BGA placement system, the first Z-axis and

retractable Y-prime movable heat zone, the first

with ultra-thin nozzles that don't disturb adjacent

components, the first with a truly modular BGA

system, the first with theta locking nozzles, the

first with countdown timing, the first BGA system

with ramping bottom-side preheat and more. We did it

first long ago and our customers from those days are

still using their gear today. Dependability and

quality!

There's no reason to risk throwing your company's

good money away and getting stuck on unproven, new

BGA "machines" that may not even be around next

year.

You

don't need to take a chance with your PCB work

when your bench can have the

ZT-7. The

same ZT-7 used by the most prestigious companies on

the planet, that has a proven history since 1998,

that is manufactured with quality and pride here in

the U.S.A., and that ships with a 2-year limited

warranty. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

How To:

RE-DRESSING BGA & PADS WITHOUT SOLDERING IRONS & WICK

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

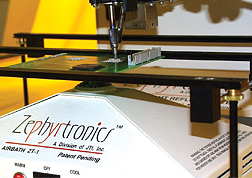

STEP 1: BGA

removal requires cleanup as unequal

solder deposits will still remain at

vacated site. After chip removal, slide

the “Y” Axis of ZT-7 back out of way,

and apply flux to pads. Begin preheat to

the bottom of the PCB at 150°C with

the

AirBath™. |

|

STEP 2 (OPTION “A”):

After briefly preheating

(soaking) your PCB and generously

applying flux, use a heated

DeSoldering Tool with a “soft tip-pad

interface” and suck up excessive solder

from your pads. Preheating permits

lower, safer temps for all

DeSoldering tasks. |

|

|

|

"Vision Award" Awarded to Zephyrtronics in Recognition

of Its Breakthrough

"AirBath Device" for Preheating at the Benchtop |

|

The

Zephyrtronics AirBath is Featured in Ray Prasad's

Definitive Text

"Surface Mount Technology" |

|

"Innovative...simpler, safer way to

remove and repair sensitive devices" The Editorial

Staff, SMT MAGAZINE |

|

|

|

|

|

|

|

|

|

|

|

|

| |

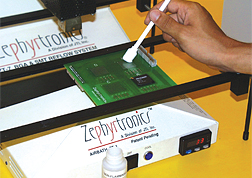

STEP 2 (OPTION “B”):

A popular method is to

generously apply flux and

melt

LowMelt®

DeSolder into the residual solder on the pads

with the

AirBath™.

Remove all solder with a foam swab or Solder Sucker |

|

|

TM

STEP 3:

Switch off the ZT-7 and the

AirBath. Gently clean site with a foam

swab and a Non-Flammable Flux Remover.

Inspect. (Notice? No Wick!) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

| |

|

©1996 - 2011, 2012, 2013, 2014, 2015, 2016, 2017, 2018,2019,

2020, 2021- 2025 by Zephyrtronics®. All rights reserved.

The information, text, images, photographs, charts, graphs you

receive online from Zephyrtronics® are protected by the

copyright laws of the United States. The copyright laws prohibit

any copying, redistributing, retransmitting, or repurposing of

any copyright-protected material. Zephyrtronics is the

registered trademark property of JTI, Inc. "The Science of

Zephyrtronics" and "Simplicity Through Innovation" and "Zephlux"

and "ZeroLead" and "Zero Balling" and "Zero Residue" and "Post

Cooling" and "Post Cooler" and "AirBath" and

"SolderGlide" and "ZeroTouch" and "SolderMill"

and "Just So Superior" are the protected trademark

property of JTI, Inc. "Zephyrtronics" and "Low Melt" and "Air

Fountain" and "Fountainhead" are the registered trademark

properties of JTI Inc. *The above names are the registered

property of their respective owners. |

|

|

|

|

|

|

|

| |

|

| |

|

SMD Rework,

SMT Rework

AirBath Air Bath,

SMD Rework Stations,

Hot Air Pencil Soldering,

BGA Rework Stations,

CSP Rework Stations,

Preheating Systems,

PCB Preheaters,

Pre-Heat SMT/ SMD,

Low Temp Rework,

SMT DeSoldering Tools,

Vacuum Pickup Tools,

Circuit Board Holders,

PCB Fixture & PCB Holders

&,

Board Cradles,

Rework Solder Paste,

No-Clean Solder Paste,

Low Melt®

De-Solder Wire,

DeSolder Wire,

Hot Air Rework Stations,

Fume Extractors,

SMT Dental Probes,

SMT, SMD Rework Kit,

BGA Rework Kit,

LMK Kit,

BGA Re-Balling Kit,

SMD Tweezers,

Power Palm Plunger,

QFP Lead Straightener

How To - SMT,

CSP, BGA Rework

How To - BGA Alignment;

How To - SMT Rework;

How To - PCB Preheating,

How To - BGA & CSP Rework;

How To - Quickly Solder

SMD Packages Effectively;

How To - CSP Alignment;

How To - Lead-Free Rework;

How To - SMD Removal

Economical;

How To - SMD Removal

Professional;

How To - Hot Air Pencil /

AirPencil Soldering;

How To - SMD Quick Chip

Removal;

How To - BGA Re-Balling;

How To - Rework PLCC, QFP,

QFN, LCC, SOIC, SOL, Shielded SMD, TSOP;

How To - Solder & Rework

Ceramic Capacitors;

How To - Solder & Rework

Glass Diodes;

How to Repair Smartphones,

Tablets and Laptops

Soldering,

De-Soldering

Soldering Accessories,

Solder Wire,

No-Clean Solder Wire,

Eutectic Solder Wire,

Solder Wire Dispenser,

Solder Paste,

Lead-Free Solder Paste,

Flux,

Solder Paste Dispensers,

Low Melt®

DeSolder Wire,

De-Solder Wire,

Soldering Tips,

Thru-Hole DeSoldering

Tools,

DeSoldering Tips,

Tips for DeSoldering,

De-Solder Wick &

DeSoldering Braid,

Smoke Extractors,

Fume Extractor Filters,

Carbon Activated Filters,

SolderMill™,

Solder Sucker / DeSolder

Pump,

Pre-heating Systems,

Preheat Thru-Hole,

PCB Pre-heaters,

Flux Solvent,

How To - Connector Rework;

How To - PC/104 Soldering

and Rework;

How To - Thru-Hole /

Through Hole Desolder / De-Solder;

How To - Low Melt®

Desolder Wire;

How To- Stop Lifting Pads;

How To- Desolder /

De-Solder Heavy Ground Planes;

How To - Lead-Free

Soldering and De-Soldering;

Pre-Heaters for Lead-Free Rework and Soldering

Dispensing Equipment, Gear, Supplies, Dispensing

Bottles & Dispensing Accessories

Dispensing Systems,

Dispensing Syringes,

Dispensing Barrels,

Tapered Dispensing Tips,

Blunt Needles,

Dispensing Bottles,

Stainless Steel Needles,

Dispensing Needles,

Industrial Needles,

Dispensing Tips,

Industrial Dispensing

Tapered Tips and Needles,

Dispensing Accessories,

Flux Bottles,

Solder Paste in Syringe,

Paste Rack Solder Paste

Holder™,

Dispensing Supplies,

Power Palm Plunger,

Manual Dispensing,

Alcohol Pump Bottles,

Automatic Dispensing,

Squeeze Bottles, Wash

Bottles, Brush Bottles, Spout Bottles, Pump

Bottles

Benchtop Accessories,

Bench Supplies,

Benchtop Tools

SMD Solder Paste,

Solder Wire,

LowMelt®,

No-Clean Flux,

BGA Flux,

Rework Tack Flux,

Non-Flammable Flux Remover,

Pen Vac,

SMT Tweezers,

Fume Extraction,

SMD Tweezers,

PC Board Fixtures,

Hot Air Tips,

AirTips,

Replacement Soldering

Sponges,

Iron Plated Soldering Tips,

Foam Swabs,

Anti-Static Foam Swabs,

Thru-Hole & Solvent

Brushes,

Helping Hands,

LMK Rework Kits,

X-BOX 360 Repair,

Wire Strippers & Wire

Cutters,

Flush Cutters, Micro

Shears & Needle Nose Piers,

Straightening Tool for QFP

Leads,

ESD Wrist Straps,

ESD Wrist Strap Tester

Updated

for

March 25, 2025 |

|

|

|

| |

|